您当前的位置:商助贸易宝 » 东丰商助贸易宝 »东丰产品 » 库存充足的精密管基地

库存充足的精密管基地

更新时间:2025-12-29 15:39:17 ip归属地:辽源,天气:晴,温度:-20--2 浏览:1次

- 发布企业

- 大鼎金属材料(辽源市东丰县分公司)

- 报价

- 电议

- 品牌

- 电议

- 供货总量

- 电议

- 运费

- 电议

- 关键词

- 无缝钢管

- 所在地

- 高新区新东环路路西钢材市场58号

- 联系电话

- 18762195566

- 手机

- 18762195566

- 联系人

- 孙经理 请说明来自商助贸易宝,优惠更多

详细介绍

以下是:辽源市东丰县库存充足的精密管基地的产品参数

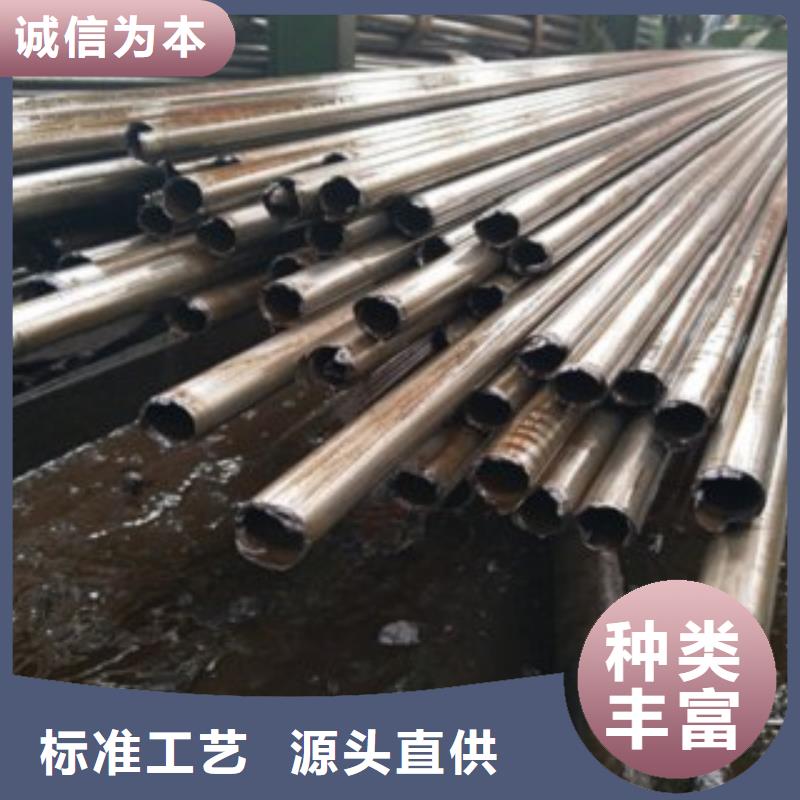

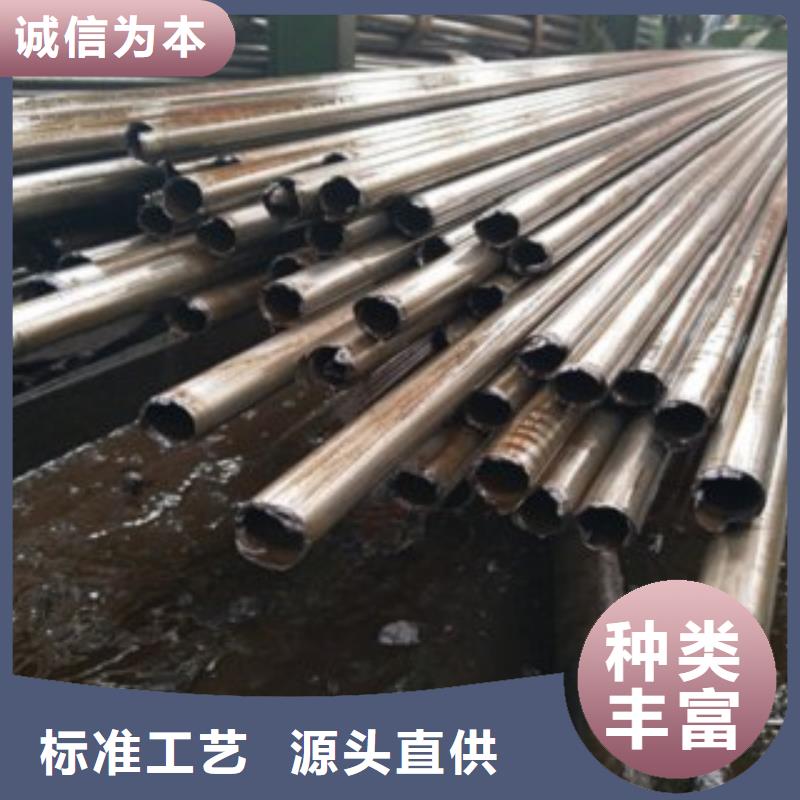

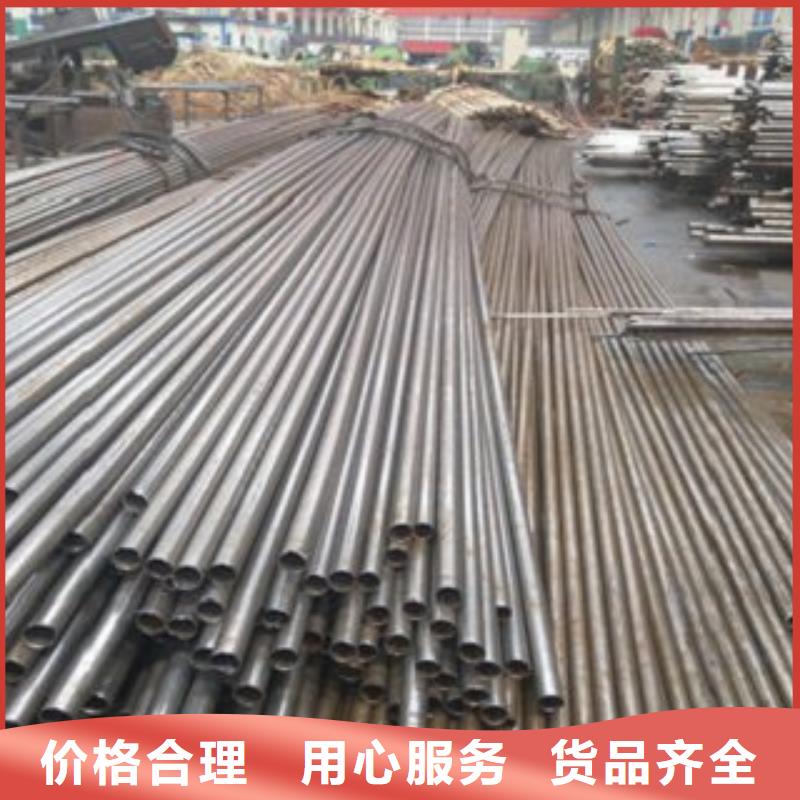

【大鼎】为您提供东辽无缝钢管讲信誉保质量等多元产品与服务。库存充足的精密管基地,大鼎金属材料(辽源市东丰县分公司)为您提供库存充足的精密管基地产品案例,联系人:孙经理,电话:【18762195566】、【18762195566】。 吉林省,辽源市,东丰县 清代被辟为盛京围场,史称“皇家鹿苑”,素有“中国梅花鹿之乡”的美誉,全县鹿茸产量居全国之首,是全国商品粮生产基地县,全国三个民间绘画画乡之一,并获得全国绿化百佳县、全省森林防火先进县、生态示范县、吉林省林业工作先进县、全国村庄清洁行动先进县。

我们的现场实拍视频将带您走进库存充足的精密管基地产品的世界,让您亲眼见证其优点和特点,为您的购买决策提供有力支持。

以下是:辽源东丰库存充足的精密管基地的图文介绍

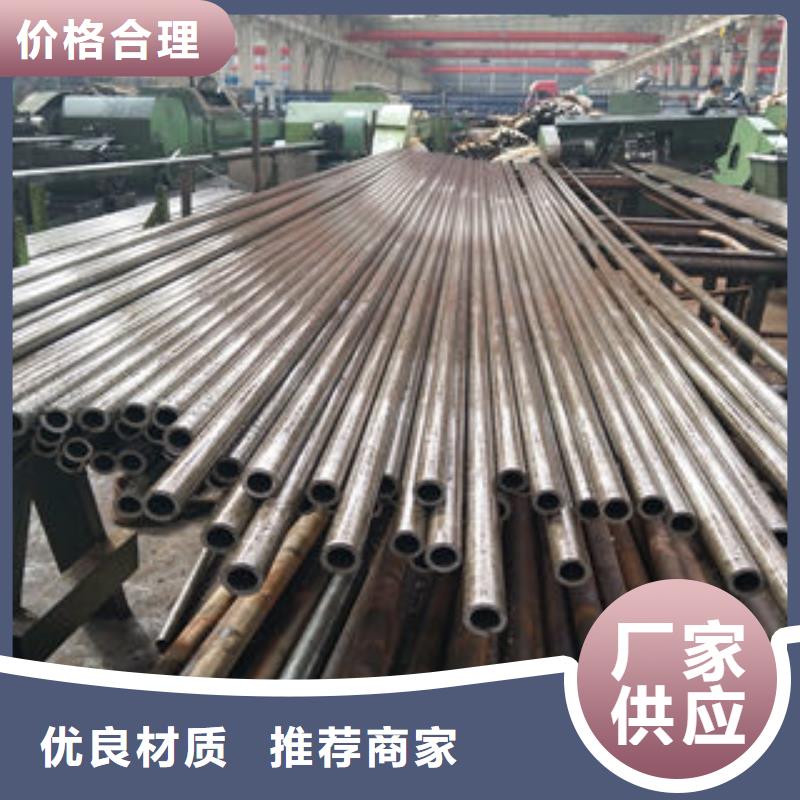

3月份以来,国内无缝钢管的产量一直在放缓。中国2012年10月无缝钢管产量为248万#,比去年同期增长8.6%;1-10月无缝钢管累计产量达到22859万#,比去年同期增长6.9%。它也可以快速升级。中国无缝钢管产量在2018年11月为25.72亿,比去年同期增长299000,同比增长13.2%,同比增长3.71%,一月至十一月累计生产256.35亿。8.2%的蔗糖。公司主要生产产品:大口径厚壁直缝埋弧焊钢管、方管、矩形管、锥形管、非标钢管、复合钢管、无缝钢管、水电管、热膨胀钢管、热膨胀无缝钢管、拉杆。GE直径钢管、不锈钢管、低合金、合金钢管等,可根据用户要求制造。钢管材质为:Q23 5B、Q345 B、Q345 C、Q345 D、Q345 QD(桥梁专用钢管)、15CrMo、30CrMo、耐磨钢管、X46、X60、X70系列等非标特种钢管。

的 无缝钢管生产制造能力,让您省心

①现代化高科技生产,配有先进生产 无缝钢管设备及检测仪器

②公司合作有多处生产基地供货以确保订单完成率

③ISO9001国际化生产流程管理,致力于成为国内 无缝钢管设计、研发、制造、生产基地

A single position gas cooled quenching furnace is cooled by jet cooling in the heating chamber after heating and holding. The cooling rate of gas cooling is faster than that of oil cooling, and quenching is lower than that of molten salt isothermal quenching. Therefore, continuous injection of cold chamber pressure, large flow rate, the use of molar mass less than nitrogen and argon inert gas helium and hydrogen are the mainstream of vacuum quenching technology development.

使流体管道的成本是很便宜的,和管道本身的强度很高,已被广泛应用于交通运输。流体管道可分为无缝管和焊接管,如果它们根据制造工艺进行区分。焊接钢管可分为其他类型的焊接管、比尔螺旋焊管、埋弧公司经营高质量无缝钢管销售地区涵盖所有省份和地区,除海南外,其他省份和地区。

硬度与变形编辑器采用两种模式,一种是研究不同变形程度对硬度的影响,另一种是研究不同温度对性能的影响。冷变形的强化在实际生产中具有重要意义。First of all, this is an important means of strengthening materials, especially for materials that cannot be strengthened by heat treatment.

山东大鼎钢管厂This is good for steel demand, including insulation and corrosion resistant tube mill cold-drawn (rolled) seamless steel pipes: round billet heating, piercing, tapping, annealing, pickling coating (copper) multi-pass cold-drawn billet tube heat treatment, straightening, water pressure test mark storage. Hot-rolled steel pipe is composed of continuous casting slab or blooming slab. It is heated by walking beam reheating furnace and descaled by high-pressure water into roughing mill. The rough material is cut into the head and tail and then enters the finishing mill, which is controlled by computer. After finishing rolling, the coiler is coiled into a straight coil through laminar cooling. The head and tail of straight curly hair are usually tongue shaped and fishtail, with poor accuracy 不锈钢厂出口价格没有上涨,钢材贸易促销利息反弹飞涨,价格形势严峻,利润微薄,企业销售一直无法打折,并且价格认可”加强,主要维持稳定。但是,随着经济条件的恶化,国民经济体制一般会保持无序,难以发挥很大的优势。上周,电线和指纹报价系统主要是平价和折扣;上周,冷轧、热轧和中板报价主要是战盘,但单位钢报价也略有下降。消费和资本注入正在改善,通胀压力正在下降,这为进一步放缓提供了更好的基础,

Oil quenching causes surface deterioration easily. Due to the high surface activity, significant thin layer carburization can occur under the action of short and high temperature oil film. In addition, the adhesion of carbon black and oil on the surface is not conducive to simplifying the heat treatment process. The development of vacuum quenching technology mainly lies in the development of single gas cooled quenching furnace with excellent performance. Double chamber furnace can also be used for gas quenching (front chamber air jet cooling), but the operation of the two stations makes it difficult to load a large number of furnace, and easy to cause workpiece deformation or change the direction of workpiece quenching. NG deformation during high temperature movement.

山东大鼎钢管厂公式计算钢管的理论重量:W=(D-S)*S*0.02466,其中W=钢管每米的重量;S=钢管的公称壁厚;D=钢管的公称外径,光亮管的表面质量i清洁、无氧化层、无裂纹、折叠、轧制、结疤、分离层和条纹。

库存充足的精密管基地_大鼎金属材料(辽源市东丰县分公司),固定电话:【18762195566】,移动电话:【18762195566】,联系人:孙经理,高新区新东环路路西钢材市场58号。